3D-MID in DEPTH and DETAIL

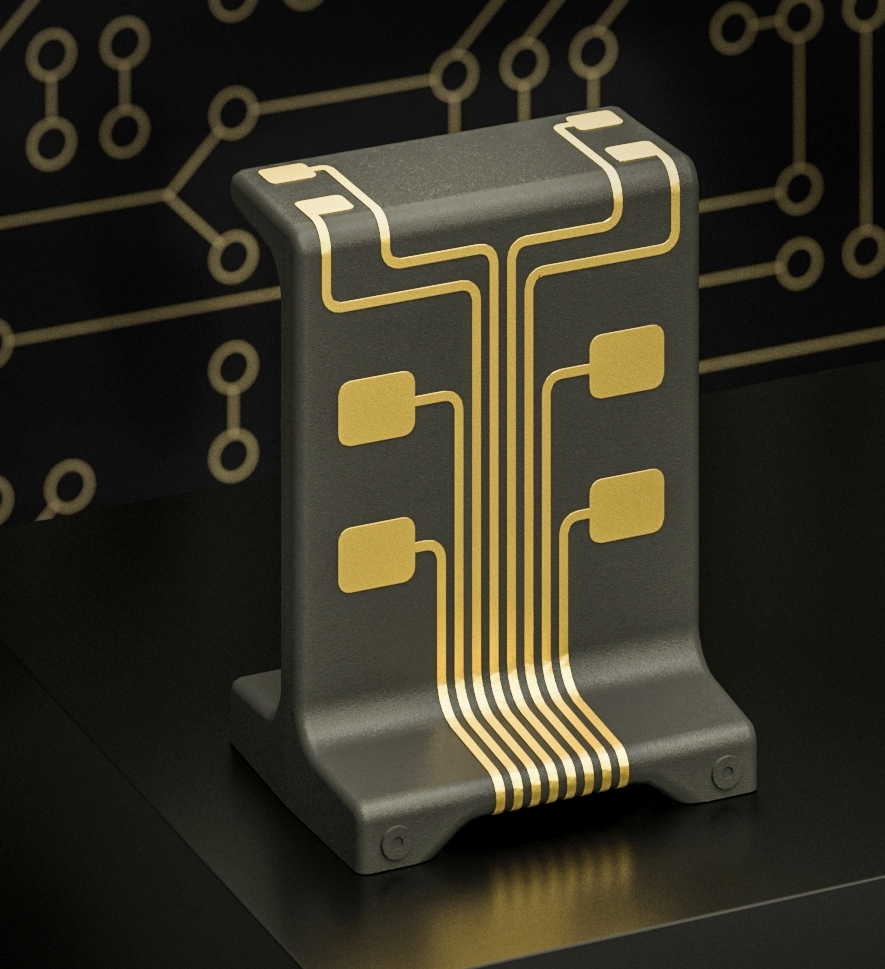

3D-MID (Mechatronic Integrated Devices) bieten die einzigartige Möglichkeit, elektronische und mechanische Funktionen in einem dreidimensionalen Bauteil zu vereinigen.

Die Basis bilden hochflexibel einsetzbare Kunststoffteile, die im Spritzgussverfahren genau nach Bedarf hergestellt werden.

Im Laser-Direkt-Strukturierung-Verfahren (LDS) versehen wir diese Teile dann mit elektronischen Leiterbahnen. Durch die Ausnutzung des dreidimensionalen Bauraums bietet die Technologie ein höchstmögliches Maß an Freiheit.

Die damit verbundene Integration mechanischer und elektronischer Funktionen auf kleinstem Bauraum sorgt für Platzersparnis und unterstützt die Miniaturisierung.

3D-MID (Mechatronic Integrated Devices) bieten die einzigartige Möglichkeit, elektronische und mechanische Funktionen in einem dreidimensionalen Bauteil zu vereinigen.

Die Basis bilden hochflexibel einsetzbare Kunststoffteile, die im Spritzgussverfahren genau nach Bedarf hergestellt werden.

Im Laser-Direkt-Strukturierung-Verfahren (LDS) versehen wir diese Teile dann mit elektronischen Leiterbahnen. Durch die Ausnutzung des dreidimensionalen Bauraums bietet die Technologie ein höchstmögliches Maß an Freiheit.

Die damit verbundene Integration mechanischer und elektronischer Funktionen auf kleinstem Bauraum sorgt für Platzersparnis und unterstützt die Miniaturisierung.