Products & Solutions

Han-Smart® - Intelligence in the connector for the Smart Factory

Connectors with extra functionality can be used in many different applications, such as machinery identification, energy measurement and surge protection.

What is a Smart Factory?

A smart factory is a broad term that encompasses the use of IoT Technologies to bring intelligence to the factory floor. Some key technologies associated with a smart factory include data processing capabilities, interconnected devices, and advanced robotics. The goal of a smart factory is to enable a high degree of customization, rapid design and system changes, predictive maintenance models and improved operational efficiency.

Han-Smart® is the Smart Factory connector

Intelligence in the connector – this is the Han-Smart® strategy. HARTING combines many years of connectivity expertise with advanced technology to extend the portfolio of established HARTING connectors. The products that will be used for smart industry applications must meet the new demands for dynamics and versatility. Manufacturing can be made more cost-efficient by strengthening communication and networking using smart connectors.

Smart services enable the customer to minimize facility downtimes through predictive maintenance. Smart connectors with extra functionality can not only receive data, but can also process and forward data to other systems. They can be used in many different applications, such as machinery identification, energy measurement and surge protection.

Surge protection for sensitive electronic components

A company’s profitability depends on their ability to minimize downtimes for their facilities and machines. Unplanned outages, such as those caused by negligence, fire or overvoltage, represent significant costs. The costs associated with downtimes can escalate rapidly; they depend on the application, the particular industry, and the size of the company. According to a study in the F&B sector, unplanned outages result in average costs of $6,000 to $12,000 per hour (Source: http://www.videojet.de). When a machine breaks down in the automotive sector, the related outage costs can be up to 22,000 USD per minute (Source: http://www.it-production.com).

Surge protection integrated into the smart connector

Surge protection for electronic components often requires separate, external solutions that demand more space and installation work. The new Han® Surge Protection Module from the Han-Modular® series adds surge voltage protection in the connector, which makes the system integration process much easier. Installation is quick and easy. The module is normally already included in the basic configuration of the connectors being used.

Your benefits at a glance:

- Surge protection without relying on seperate, external solutions

- No additional installation work needed

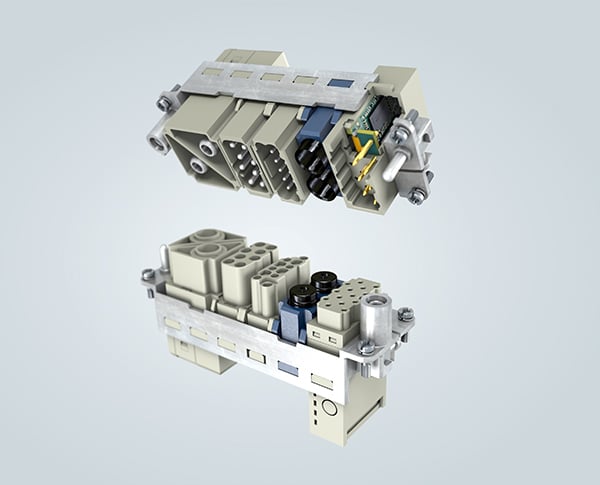

Identifying facility components

Modularly designed manufacturing equipment is becoming essential because of the increasing flexibility of industrial manufacturing. Adding such equipment to existing facilities should be an intuitive plug-and-play process. More mating cycles are required in smart factories, since machines, modules and tools must be frequently replaced. Faulty plugging can result in considerable losses of time and revenue.

Integrated into machines that use pluggable drives, auxiliary devices and/or other components, the ID module helps to determine whether all components are connected at the right position. Sources of faults are detected quickly, so that a faulty configuration can be avoided right from the beginning.

When combined with the HARTING IIC MICA® additional opportunities arise: information about the facility components (e.g. year of manufacture, revision status and other component parameters) can be saved in the ID module and be provided for an application's predictive maintenance.

Your benefits at a glance:

- Identifcation functionality combined with storage options for peripheral devices

- Saves time and reduces service costs

Ethernet networking via connector

Manufacturing processes are becoming increasingly modularised and more flexible. Powerful, durable connections which can supply machine components with data, signals and power are essential for these processes. Han-Modular® has established itself as the market standard for modular connectors. Entirely new possibilities are opened up by their integration of electronic components.

More Ethernet devices

For state-of-the-art forward-looking facilities, the number of devices requiring an Ethernet supply is increasing steadily. For example, industrial image processing has become a basic technology in modern manufacturing processes. In order for this technology to be seamlessly integrated into industrial manufacturing systems, there must be an intelligent and reliable supply of power and data available.

The interfaces play a crucial role here. At all levels of the manufacturing process, machine components are connected using pluggable connectors. Switch functionality is also finding its place inside such connectors. This makes it possible to install network nodes closer in the field and on-site. Subsequent installation efforts for adding new Ethernet devices are significantly reduced.

Your benefits at a glance:

- Easy to add new ethernet devices

- More freedom when creating topologies