HARTING partners with RS Components to support their robotics campaign

RS Components, a leading distributor of electrical, electronic and industrial components, has a long-standing partnership with HARTING. Therefore, it is no surprise that when they were discussing the launch of their robotics campaign, HARTING were the first manufacturer to come to mind.

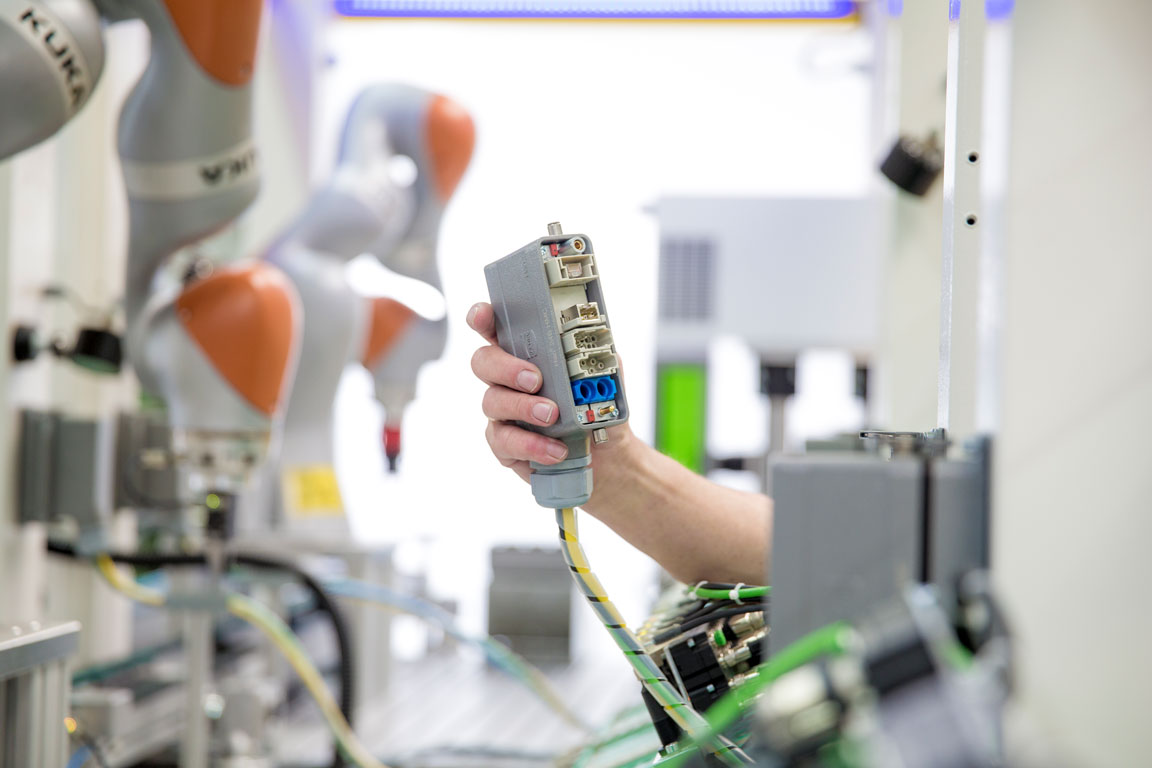

David Pike, the IP&E Merchandising Manager of RS Components, flew out to Germany to speak to Dr. Volker Franke, the General Manager of HARTING Applied Technologies. The focus of the trip was to discuss HARTING’s use of robotics within their factories and to discover how we integrate our own products within the production process in order to create a more automated factory.

Watch the video to learn more about the importance of robotics within HARTING’s manufacturing process.

Whilst there, David was also introduced to the HAII4YOU application (HARTING Integrated Industry 4 You). The HAII4YOU factory unit is comprised of three production cells, each with their own control system. The unit shows individually customised Han-Modular connectors being manufactured, demonstrating how customised products can be produced under mass production conditions.

The factory also demonstrates the six trends of Integrated Industry.

Modularisation: Modular production plants provide a new level of flexibility, future-proofing interfaces and infrastructures and simplifying upgrades and extensions.

Identification: Plant modules and products must be uniquely identified for an efficient and smooth process. RFID solutions provide you with real-time control of your production processes and maintenance.

Integration: Reliable production processes require vertical integration at the field level and corporate control. System integrators combine Smart Objects and ERP with flexible software solutions to provide a comprehensive integration of all production elements.

Customisation: Mass production can now embrace customisation, meaning industrial production is getting more intelligent and more flexible, increasing the availability of customised solutions.

Miniaturisation: The digitalisation of industrial production requires more computing power in ever smaller spaces. Components are now required to deliver maximum performance in the smallest possible space, driving the demand for compact components.

Digitalisation: The advancing digitalisation of industrial production requires ever more intelligent hardware at field level. Our modularly constructed systems support you in the decentralised collection of data and its analysis.