The "Swissloop" project

HARTING involved in the transport means of the future

"Swissloop is a student project at ETH Zurich, consisting of about 30 Bachelor and Master students from the fields of mechanical and electrical engineering, as well as some other faculties. The aim of the project: to explore and advance Hyperloop technology.

The Hyperloop concept is pursuing the aim of replacing short- and medium-haul flights with a more efficient, faster and CO2-neutral alternative in the future. According to the concept, a so-called "pod", which transports passengers, is to speed through a tube at velocities of up to 1,200 km/h. In order to minimise the air and rolling resistance and to significantly increase the efficiency of locomotion, there is almost a vacuum in the tube – enabling the pod to float laterally and vertically without contact. Swissloop designs, builds and tests a new, innovative prototype of this pod every year - from scratch.

In this way, students learn what it means to engage in genuine, real-life engineering already in their Bachelor's degree programme. At the same time, this is how they drive the development of Hyperloop technologies forward every year.

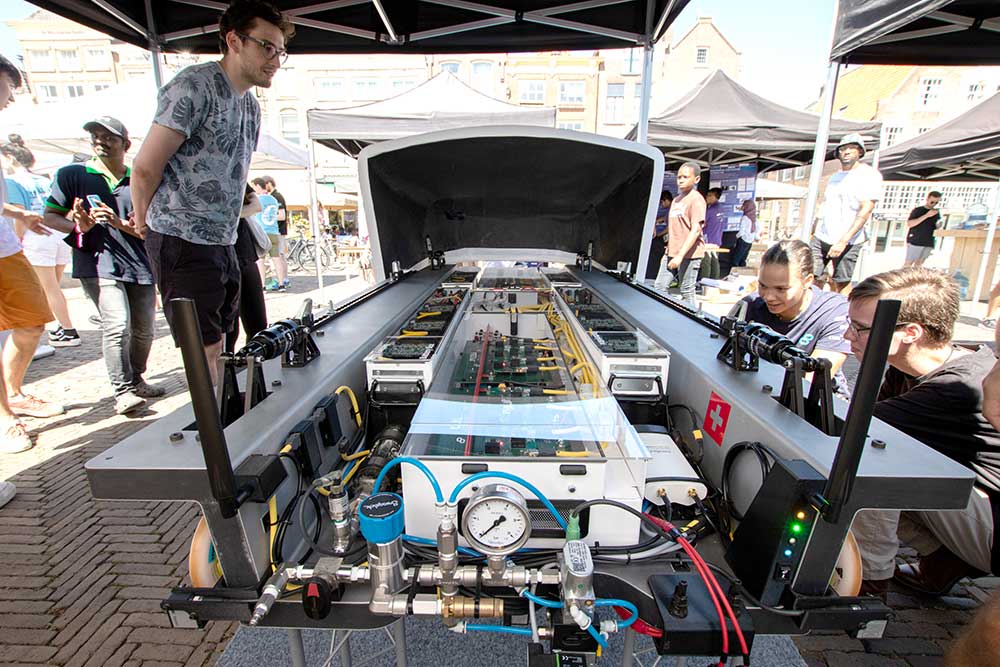

The Swissloop Pod "Lavinia Heisenberg”

After the great success of last year's Swissloop pod "Simon Ammann", which was capable of hovering thanks to its advanced "Linear Induction Motor" (LIM), this year's Swissloop engineering team set itself new and equally ambitious goals: The new pod "Lavinia Heisenberg" impresses on the one hand with its sheer size.

It Is capable of transporting a EURO pallet together with its freight. On the other hand, a "linear switched reluctance motor" (LSRM) is installed. This differs fundamentally from the previous prototypes due to its much higher, maximum efficiency - and is consequently perfectly suited for real-life use in a Hyperloop.

In addition, the students also made great progress in terms of electromagnetic interference (EMI), carbon shell design and inverter control. Finally, in addition to the construction of this year's pod, a new 33-metre steel test track developed in-house was also built at the Swissloop headquarters situated at the Dübendorf Innovation Park.

In order to compete with other student teams around the world, Swissloop travelled again this year to the European Hyperloop Week (EHW) in Delft, Holland, to demonstrate the new Swissloop pod. And successfully: The young developers were able to win both the "Traction Award" for the best drive system and the "Mechanical Subsystem Award" for the best mechanical design with their "Lavinia Heisenberg ".

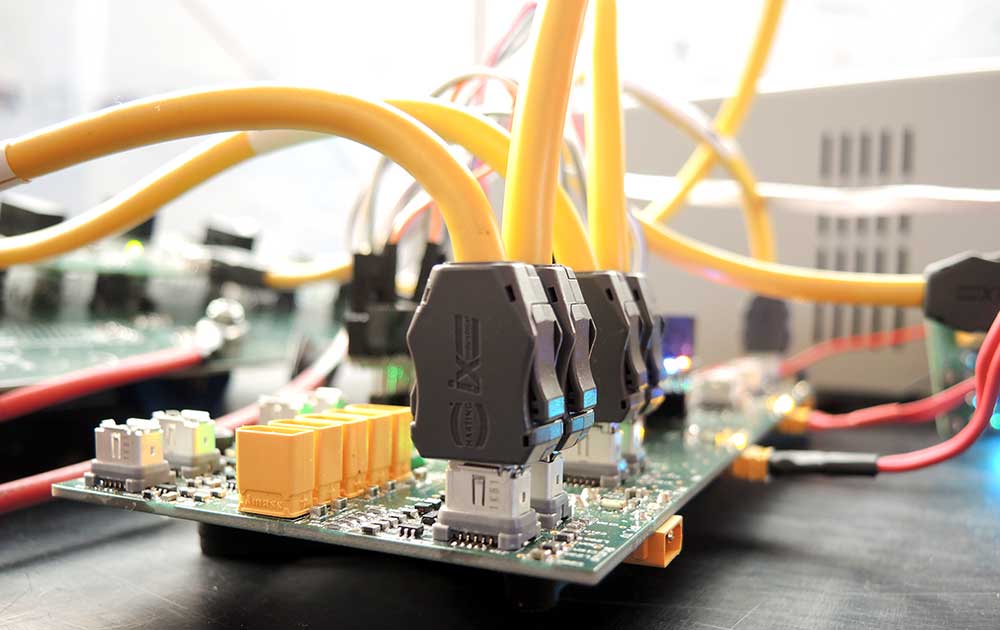

HARTING products in the Swissloop pod

This year, most of the 2022 Swissloop pod's data connections were upgraded to HARTING ix Industrial®. With this step, a uniform connector system including good shielding has been found. The HARTING ix Industrial® also scored points with its ability to easily assemble the cables to the desired length.

All the data cables from the Inverter Control Unit (ICU) to the Inverter Gate Drivers (GD) were converted to HARTING ix Industrial®, which completely eliminated EMI problems. The sensor bus operated with CAN FD was also implemented entirely using ix Industrial® cables. This saved valuable time during on-site production.