HARTING GreenLine: First carbon reduced connector components mature to market

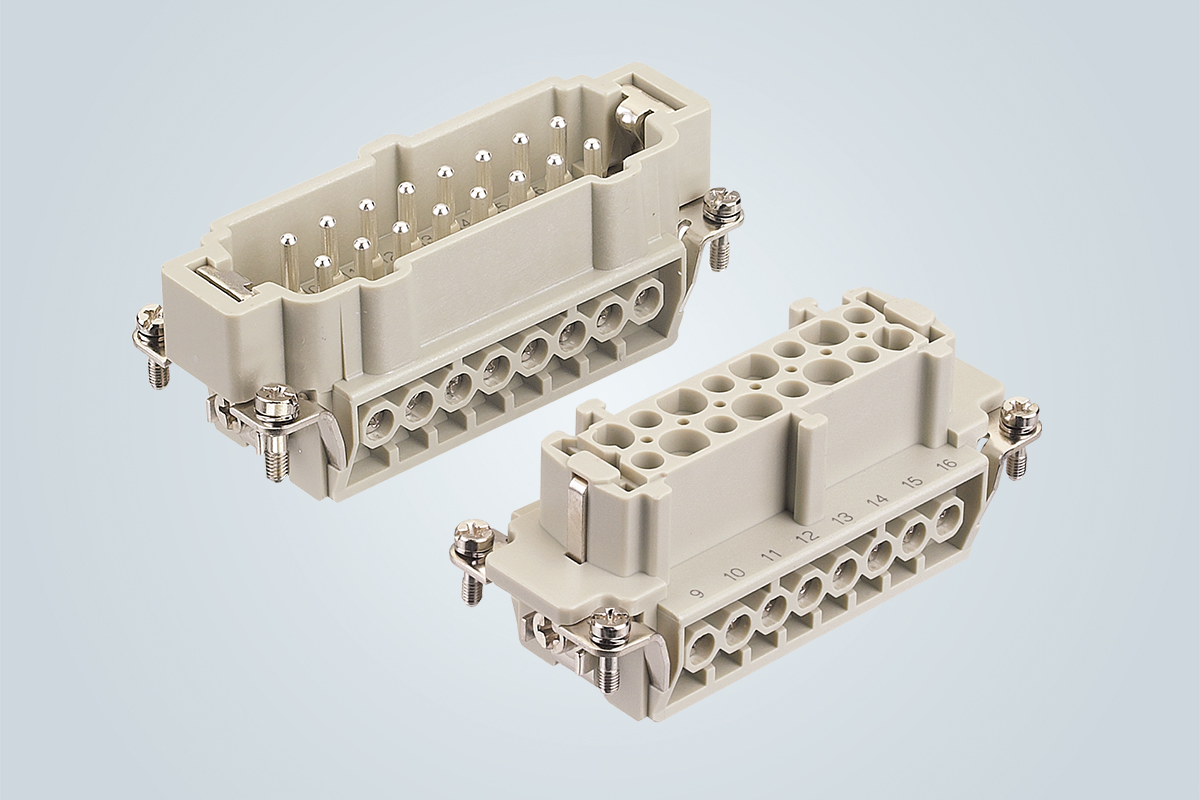

The HARTING Technology Group is living up to its responsibility for the carbon footprint of connectors, and thus is presenting the first CO2 reduced contact inserts of the GreenLine series at the Hannover Messe 2024. The carbon balance is achieved mainly by replacing mineral raw materials for the connectors with biopolymers. HARTING was the first manufacturer to produce the Han® E series in sizes 6B to 24B accordingly.

Up to 70% CO2 reduction

The new biopolymer is produced according to the principle of mass balancing, i.e. with renewable instead of fossil raw materials. It meets the criteria of the international sustainability and carbon certification ISCC+ and offers a CO2 reduction of up to 70%, based on certified, bio-based polycarbonate.

The HARTING GreenLine has a positive impact on the environmental balance of the manufacturing process of a device or machine/system at the customer’s premises. ISCC+ certification enables a complete traceability of materials used along the entire supply chain. This enables customers to improve their CO2 balance.