Open Compute Project (OCP) - Power connectors for ORV3 rack systems

The Han® ORV3 strikes the balance between standardisation requirements and achieving as much flexibility as possible.

The global demand for digitalisation infrastructure is growing rapidly. Businesses and consumers have increased their reliance on remote computing, apps, and the Internet of Things (IoT) at a remarkable speed. As a result, society has become much more dependent on tasks that require data centres, which form the backbone of everyday operations in all industries. It’s therefore essential that IT infrastructure for data centres is readily available, and any system failures are repaired quickly.

Web-Seminar | How standardisation for data centres can reduce costs and speed up time-to-market

Open Compute Project (OCP)

The base is an open exchange of ideas, specifications and other intellectual property to maximise innovation and reduce the complexity of technical components.

OCP provides their recommended data center designs free of charge, called the Open Rack. The third version of the Open Rack (ORV3) began worldwide installation at the beginning of 2023.

The OCP Foundation is responsible for fostering, serving and seeding the OCP Community to develop new open solutions that can meet the market and shape the future.

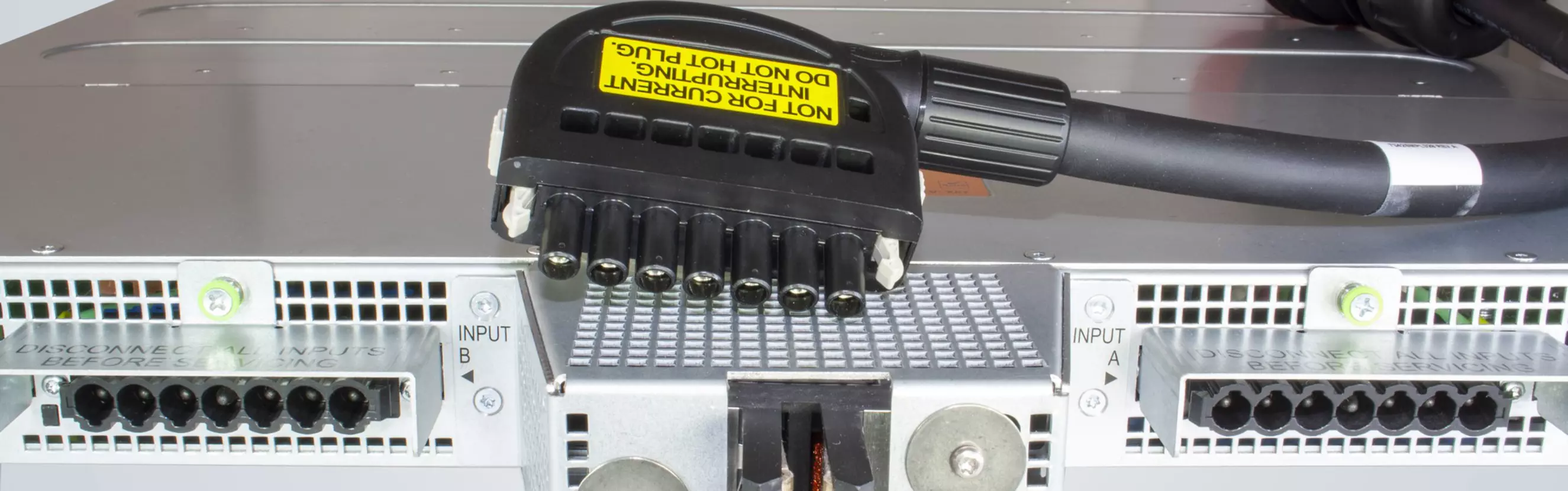

ORV3 Power Shelf

In a data centre, power shelves provide power to IT equipment. The Rack & Power Project Group within the OCP initiative is focused on standardizing racks and making them easier to integrate into the data centre infrastructure. One critical step is a common specification for “power shelf″ input connectors. As a lead author and initial connector partner in the standardisation process, HARTING has put a lot of time and expertise into the specification of the "ORV3 OCP Input Power Connector".

High availability 'Mean Time Between Failures' (MTBF) and low average repair times, 'Mean Time To Recover' (MTTR) after system failures are essential for a data centre. Complexity reduction and standardisation can help to reach these goals.

Reduce total costs of ownership

With the Han® ORV3, HARTING for the first time offers an OCP-compliant AC connector, which is also available as complete power shelf v3 rack assemblies. Shallower rack systems enable a more compact design for the entire infrastructure.

As a result, data centres can significantly increase their productivity within a given footprint. HARTING’s solution thus supports the Open Compute Project’s goal of optimising efficiency in the construction and scaling of data centres.

The Han® ORV3 for rack systems strikes a balance between standardisation requirements and the goal of achieving as much flexibility as possible in the configuration of cable assemblies for different current and voltage levels.

The Han® ORV3 component avoids complexity, as it consists of only a few part numbers. This enables high availability and, in cases of rack unit failures, low average repair times, thanks to the open ORV3 standard. Total cost of ownership is sustainably reduced.

Reduce total cost of ownership (TCO) with the Han® ORV3 power connector and pre-assembled cabling solutions

Your benefits at a glance:

Up to 50% less installation space required compared to classic rack system solutions

Rapid scalability of data centres due to the consistent modularisation of rack systems

Simple service for high volume data centre components

Complexity reduction through minimisation of SKUs thanks to OCP (Open Source System) compliance

Fast configuration of solutions for different current and voltage requirements, also made possible by convenient jumpers

Safe installation process due to touch safe contacts

High flexibility for installation due to different termination technologies: PCB and crimp

Time savings through use in pre-assembled cabling solutions for power distribution from one single source

World-wide manufacturing allows our customers to source their assemblies in region at competitive pricing