New HARTING website

Our corporate vision ‘We want to shape the future with technologies for people’ stands for the right products and for making the entire digital information and purchasing process as efficient and convenient as possible.

News Room

Discover the latest HARTING news about the company, best practice, tec.news and products

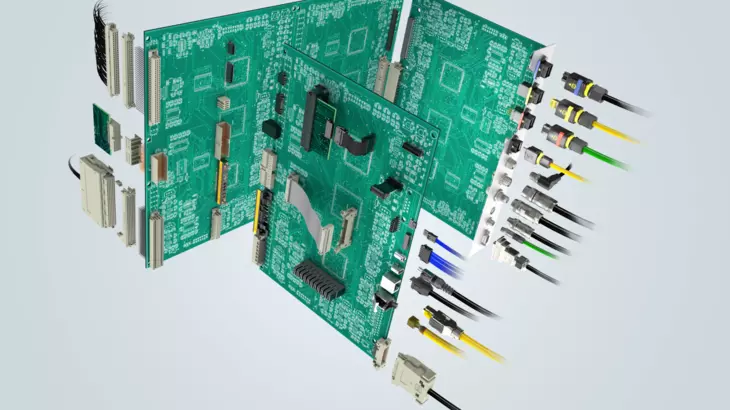

Our products

The HARTING Technology Group

100 % owned by the Harting family, around 6.200 employees, Euro 1.036 m in turnover, 14 production plants and worldwide 43 sales companies. Learn more about the HARTING Technology Group