Two for all, all for two

Daniel Deng, Head of Product Application Management

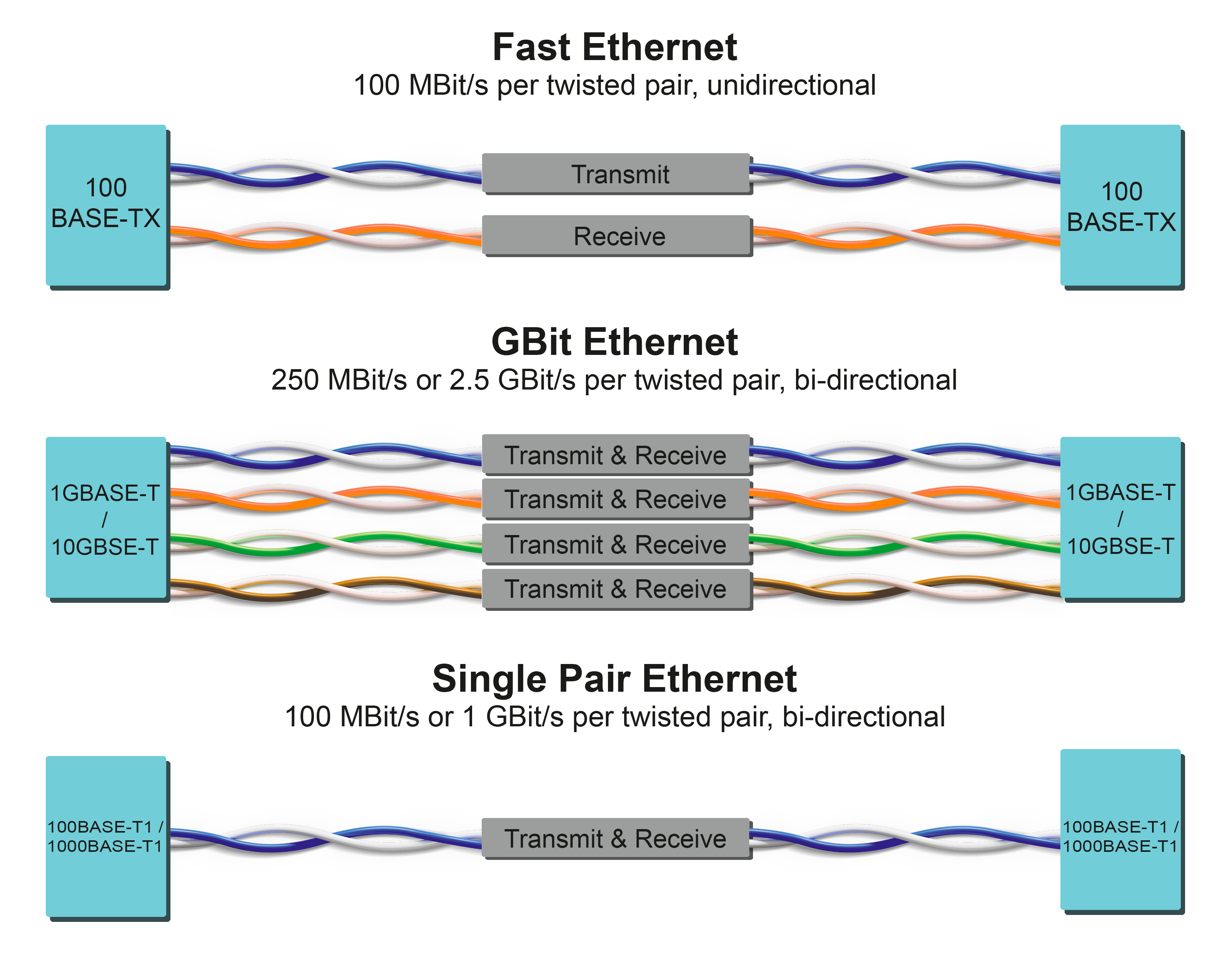

Since Industrial Ethernet has become increasingly popular, we are hearing more and more frequently claims of “from the sensor to the cloud”. These claims are normally made in connection with mega-trends such as IIoT and I4.0. This refers to continuous TCP/IP-based communications based on Ethernet, which currently mostly range from cloud applications down to the distribution level in manufacturing.

Where previously there was a classic break in communication systems between Ethernet and BUS systems, modern components can now bring fast Ethernet (up to 10 Gbit/s) to the smallest application using just one twisted wire pair. In this way, SPE enables consistent usage of the TCP/IP protocol for the first time. And this is driving the development of new devices and applications fields, especially sensor/actuator networks. The sensor becomes “intelligent” and a part of the overall network. This speeds up parameterisation, initialisation and programming. When using SPE – whether with a simple state sensor or a modern vision system consisting of a high-resolution camera – the internet of Things becomes reality and field level becomes smart.

So when and how does SPE approach the world’s factory – China?

“We shape new standards and discuss them with our Chinese partners, as communication is the way to go. We believe China is a very huge and important market, thanks to the Industrial upgrading,“ said by Joachim Finke, head of global product management, network interface connectors, at HARTING. “Smart factories require the seamless connectivity between the IT and the OT world. SPE will play a key and important role in this area. We have been preparing for this day for quite some time. Two (one pair) for all, and all for two.” As we know, China had already been considering adding SPE as the new interface in some standards, such as the GDCT (Green Data Center Technology Committee) standard, PICMG (PCI Industrial Computer Manufacturers Group). Industry ethernet white paper heighted SPE especial for the function of PoDL.

It will also integrate time-sensitive network capabilities into systems, increasing the determinism of OT networks, reducing the amount of cabling required, while making the construction and maintenance of facilities easier and more cost-effective. SPE connectors can also bring these advantages to robotics, machinery and vehicle applications, including rail systems.

In the operation field, for plant engineers, SPE makes work easier, installation is simpler compared to four-pair Ethernet and allows a noticeable reduction in space and weight. And due to reduced termination in the field from two or four pairs cable termination, the error of cable termination can be significantly reduced. In some special cases, the plant engineer or operator will require less time to detect a cable termination error.

Apart from the more compact size, users benefit from lower assembly costs, less space requirements and less weight. What’s more, SPE cable has a tighter bending radius, as well as lower heat loads and smoke generation, while the reduced use of copper benefits the environment.

For the most part, Single Pair Ethernet will not replace conventional two and four pair Ethernet, which continues to enable even faster speeds – well into the Terabit range – and other performance enhancements. Rather, SPE’s true calling is to serve where its speeds, smaller size, lighter weight and lower price make it the practical choice for meeting new IIoT requirements. Consequently, this will cement the astounding growth of Ethernet in industry. As recently as 2014, fieldbus accounted for 71 % of all new nodes installed globally, with Industrial Ethernet standing at 29 %. By 2021, that had largely reversed with 65 % and fieldbus is down to 28 % as indicated below.

Two (one pair) for all has become reality.

The SPE ecosystem is predestined for this. Right from the very outset, the SPE ecosystem has been an open minded, innovative, standardised and live alliance. In this alliance, they are no competitors, no soldiers and even companies - but only friends.