Keeping a keen eye on energy consumption

Sustainable action in industrial production stands, among other things, for the efficient and prudent use of energy. However, in order to keep an eye on the real, actual energy requirements of drives and electrical devices, these must first be validly collected, collated and evaluated. Without clear information, a meaningful evaluation and energetic optimisation is hardly possible. To this end, HARTING is supporting the "Development of Energy Management Interfaces for IoT Technologies - IoT_EnRG" research project at Hanover University of Applied Sciences and Arts and Helmut Schmidt University in Hamburg by providing smart infrastructure. The research project is concerned with developing a universal energy information model for the simplified transmission of energy management data to higher-level systems.

In recent years, ever greater focus has been placed on sustainable and environmentally conscious approaches and action. Not least due to spiralling energy prices, it is becoming more necessary than ever to keep a keen eye on consumption in one´s own production. To begin with, monitoring energy consumption is nothing new in itself. However, there are currently still various hurdles in the industrial environment that make it difficult to evaluate energy data simply and uniformly so as to achieve consistent energy management.

In the automation of industrial plants, users today have to resort to different semantics for the interpretation of energy data, as proprietary systems and parallel standards exist. With the help of semantics, energy data becomes valuable energy information. In order to ensure that this energy information is available in a uniform format, a universal energy information model has been developed over the last two years by the "Development of Energy Management Interfaces for IoT Technologies - IoT_EnRG" research project, which is funded by the Federal Ministry of Economics and Climate Protection (BMWK). With the help of this information model, energy data gains clearly defined semantics and can thereby be integrated more rapidly into the technical energy management systems with less engineering input and effort. In industry, the integration of energy information originating from an extremely wide range of different sources at the field level is currently still associated with a high level of engineering effort, as the energy data is transmitted and made available by way of different communication protocols (e.g. PROFINET, Sercos III, EtherNet/IP or Modbus TCP) and specific energy profiles such as PROFIenergy, Sercos Energy or CIP Energy. The resulting different proprietary and energy profile-specific semantics are retained when setting up OPC UA interfaces and complicate the interface configuration, as well as the further integration of the energy information into energy management applications. The universal energy information model is now able to overcome this hurdle and thereby provide a contribution that supports industry in operating cost-efficient production that is as climate-neutral as possible.

The Smart Electrical Connector as an information provider

Information on energy consumption is collected in different ways. Some devices are able to measure their consumption independently and report it to higher levels, while others require external sensors.

All in all, megatrends such as IoT and concepts such as the Digital Twin are based on a significant increase in available data. And this not only applies to active devices but also to formerly passive components such as connectors. In future, these components will not only transmit energy and data as passive infrastructure elements but will also be able to actively monitor status data such as current and voltage and thereby become a supplier of energy data.

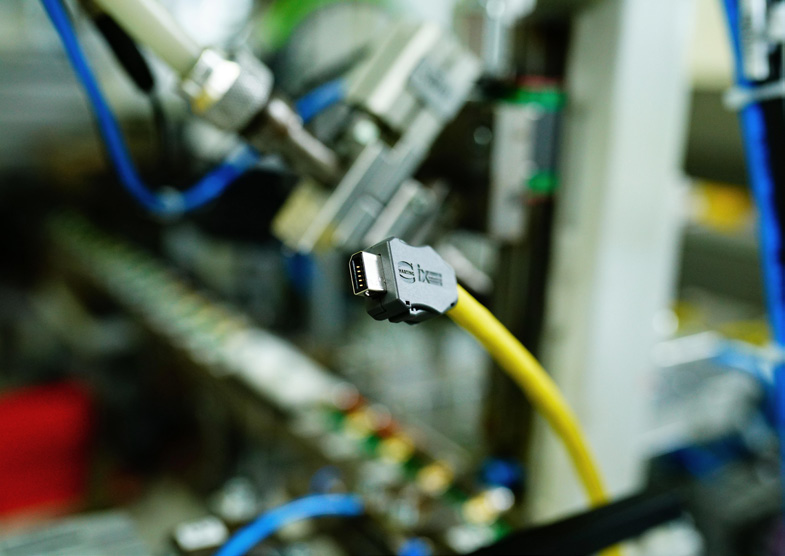

With the requirements of the IoT firmly factored in, HARTING is supporting users with concepts such as the SmEC - the Smart Electric Connector, which are capable of independently recording energy data and transmitting it by way of their own management shell. This transforms the connector into a smart component, and energy management data can thereby be generated far more conveniently.

Interview:

The "Development of Energy Management Interfaces for IoT Technologies - IoT_EnRG" research project aims to develop a universal energy information model to make data on energy consumption uniformly transferable and easier to evaluate. tec.News spoke with the project leaders Leif Thore Reiche and Maxim Runge.

Mr. Reiche, Mr. Runge, the project was transferred to the JWG Power Consumption Management and has thereby taken a step towards standardising the model. For whom is the universal energy information model interesting, who should be taking a closer look at the results of your work?

L. T. Reiche, M. Runge: The energy information model is primarily aimed at all people who deal with the transmission of energy data in industrial scenarios. In addition to professionals from the field of energy anagement, the model could, for example, also be relevant for developers, commissioning personnel and engineers who work in the energy environment.

In order to bring the model to life, a demonstrator has also been created under your leadership, which HARTING will be exhibiting at SPS 2023. In what form does the demonstrator realise your model?

L. T. Reiche, M. Runge: Sample applications such as a three-phase motor, compressed air cylinder, 3 different process valves and a servo linear drive as a consumer have been set up on the demonstrator. In addition, leakages can be simulated by a manually operated valve. Measurement data is provided starting from the operating equipment (e.g. frequency inverter), but also by way of separate measuring devices. The switches make a pivotal contribution to the distribution and provision of energy data.

How important is energy data from the field level for the product carbon footprint?

L. T. Reiche, M. Runge:

Without the energy data from the field level, the PCF cannot actually be accurately quantified. Consequently, these data are patently significant for its assessment. Without knowing exactly the consumption occurring at the field level in the course of a product creation process, it is impossible to say how many kWh of energy are in the product and how these are divided into potentially regenerative and non-regenerative components.

What approach is being taken to generate the data in the project (heterogeneous systems,

standards, universality)? What is the relationship with the Asset Administration Shell (AAS)?

L. T. Reiche, M. Runge: The demonstrator gave us the opportunity to generate energy data from heterogeneous systems in different use scenarios, which we could then measure, describe semantically in a uniform way and communicate throughout the network. There is a link to the AAS in the meaning that our information model is able to store the energy data in a semantically uniform way.

How is HARTING supporting the project?

L. T. Reiche, M. Runge: With the ix Industrial Ethernet interface, HARTING is providing an advanced, state of the art alternative to RJ45 solutions. ix Industrial is significantly more compact, but at the same time far more robust and much better shielded – thereby ensuring excellent signal integrity. Furthermore, HARTING is supporting the demonstrator with unmanaged switches that are fully suitable for the reliable distribution and provision of energy data. What is more, HARTING is pleased to provide such vital projects with a stage at SPS 2023 to showcase the significance of sustainability and energy management topics and issues.