European Train Control System (ETCS)

European Train Control System (ETCS) retrofit solutions

HARTING’s range of rail-approved products and solutions support the retrofit of rolling stock and implementation of ETCS.

Introduction to ETCS

In December 1989, representatives from EU states met to discuss the creation of a uniform European Train Control System (ETCS). The idea was the ETCS would become an internationally valid standard, offering advanced safety technology that other countries and rail operators could adopt, helping to smooth the flow of cross-border rail traffic.

What is ETCS?

ETCS allows trains to run without traditional trackside signals. Instead, a series of communication systems monitor the train’s position and speed and relays information to the driver’s cab. For example, real time data is transmitted via transponder balises between the rails and via track control centres.

These systems know exactly where the vehicle is and automatically issue travel clearance, allowing the train to move safely along the track. For additional safety, the driver can take manual control if required. The aim of ETCS is to make rail traffic safer and more attractive for travellers. The harmonised control system allows for increased travel speeds, shortening journey times. It also improves the efficiency of trains, allowing them to travel closer together and providing a better service for travellers. In addition, because it is a Europe-wide system, it reduces the need for disconnecting and changing trains, meaning more non-stop journeys are possible.

As we have seen, the benefits of ETCS are numerous and one reason why new locomotives are being designed and equipped with the technology required to run the system. However, older rolling stock will need upgrading and retrofitting with cabling, wiring and connectors to run the ETCS system.

HARTING have a wide range of rail-approved products and solutions to support the retrofit of rolling stock and implementation of ETCS. Some of our solutions include:

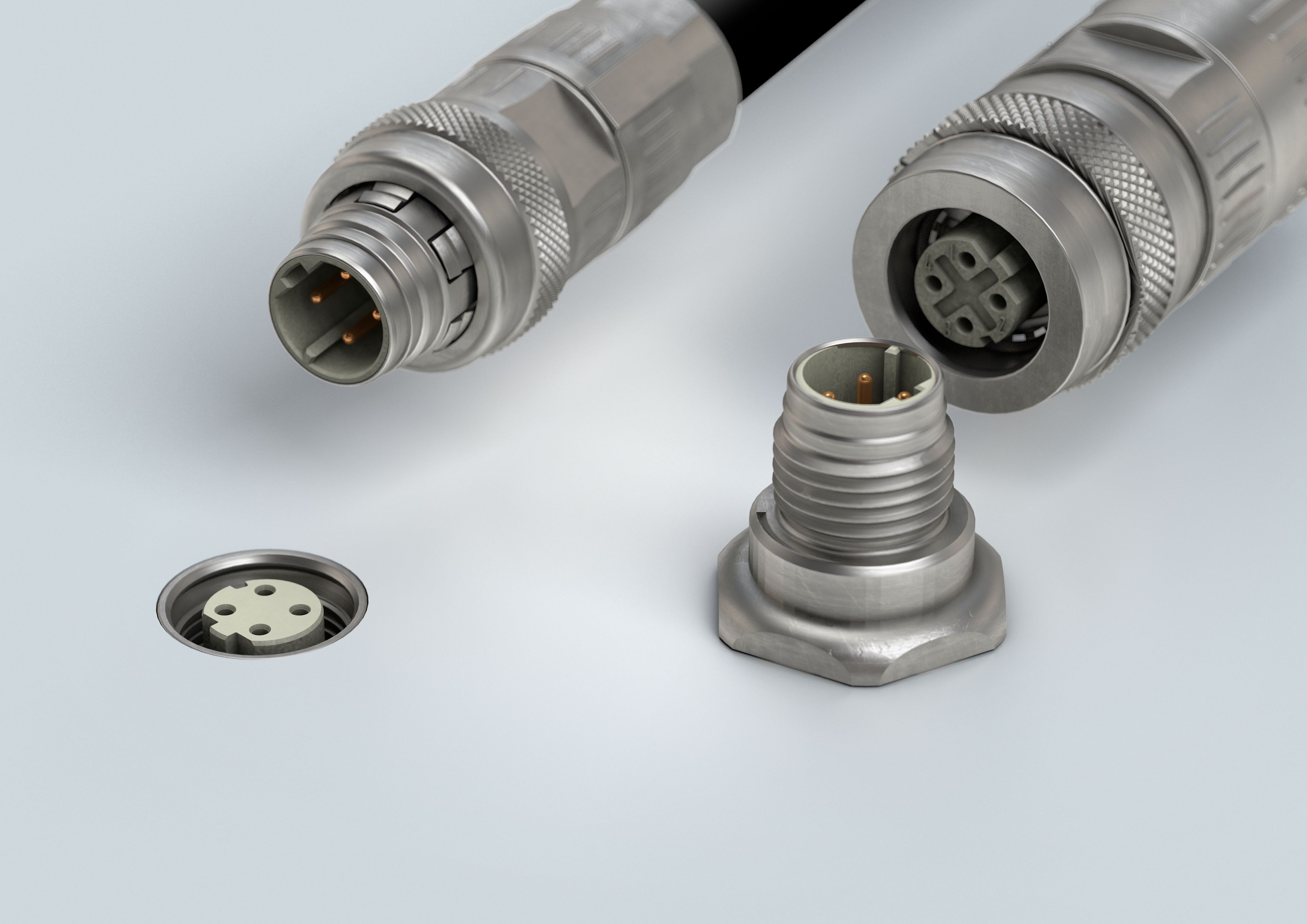

M12 PushPull: Interior fitting and retrofit work in trains is often awkward due to restricted space conditions, meaning easy installation is crucial. The M12 PushPull is the solution, offering handling, time saving and reliability benefits. M12 PushPull uses a tool-free connection technique that ensures absolute reliability and means the assembly density can be significantly increased, helping to save valuable space.

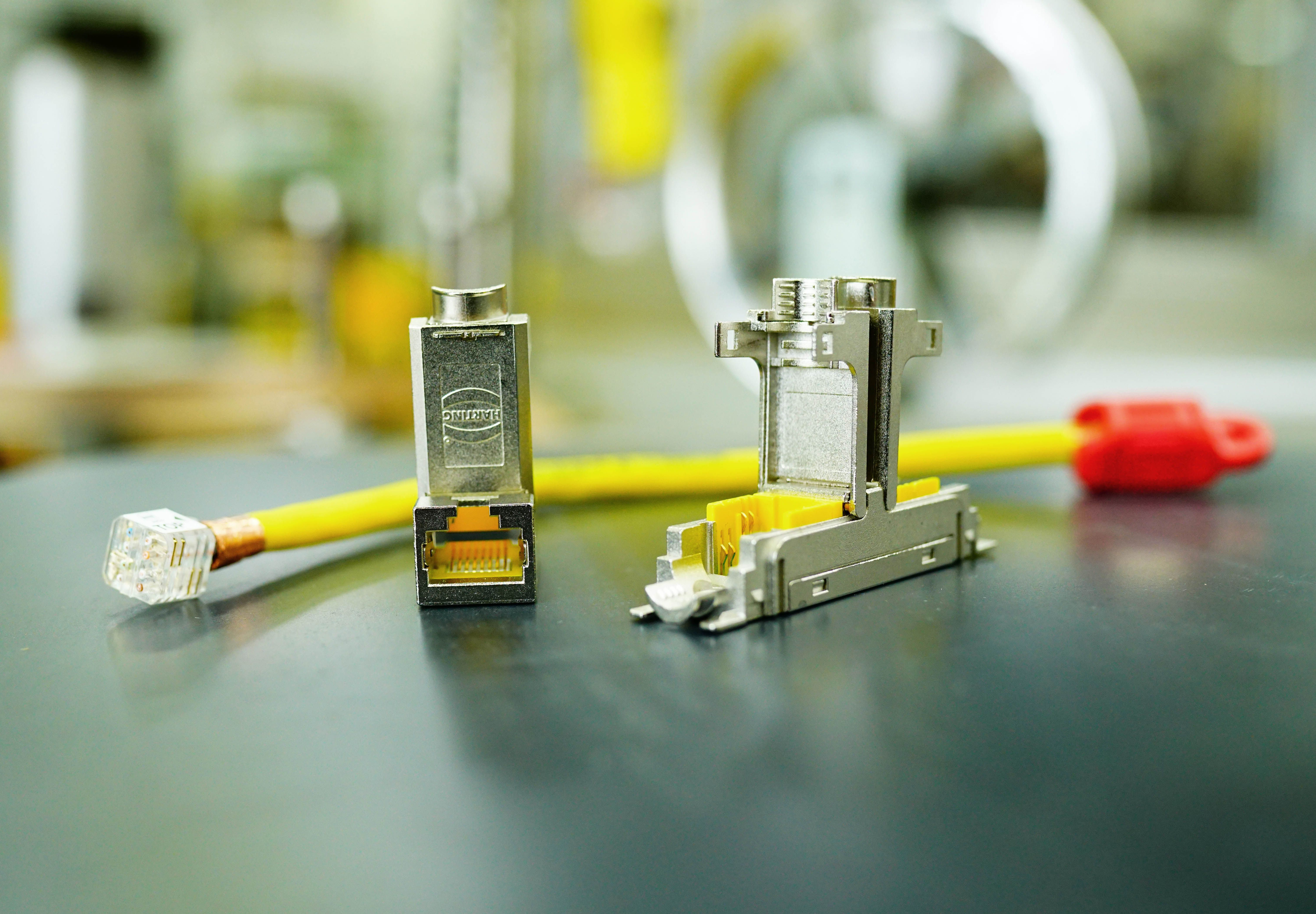

preLink® and EtherRail®: Used in combination, HARTING’s preLink® system and Ha-VIS EtherRail® cables allow you to build secure data networks in trains. EtherRail® cables are specially designed for railway requirements whilst the preLink® contact block allows you to pre-fabricate data cables outside the carriage before installing them, resulting in a reliable, simplified assembly.

Han® HPR Compact: The Han® HPR series is ideal for transmitting high power, high voltage, signal or Ethernet data in exposed areas. It can be used for bogie mounting, roof mounting and as jumper cables between carriages. The new Han® HPR Compact hoods and housings require 20% less installation space and are 25% lighter than conventional solutions. Up to two frame extenders can be attached to the bulkhead mounted housing, increasing the available space for wiring.

PCB Connectors: HARTING offers a range of solutions for connecting PCBs. D-Sub variants for transmitting signals, data and high currents are available. For example, the D-Sub Mixed offers nearly unlimited choices to satisfy your requirements. The miniaturised design and flexibility of har-flex® offers a freely scalable connection technology which can transmit data, signals and power. har-modular® gives you over a billion combination possibilities and allows you to create a bespoke design using an online configurator.

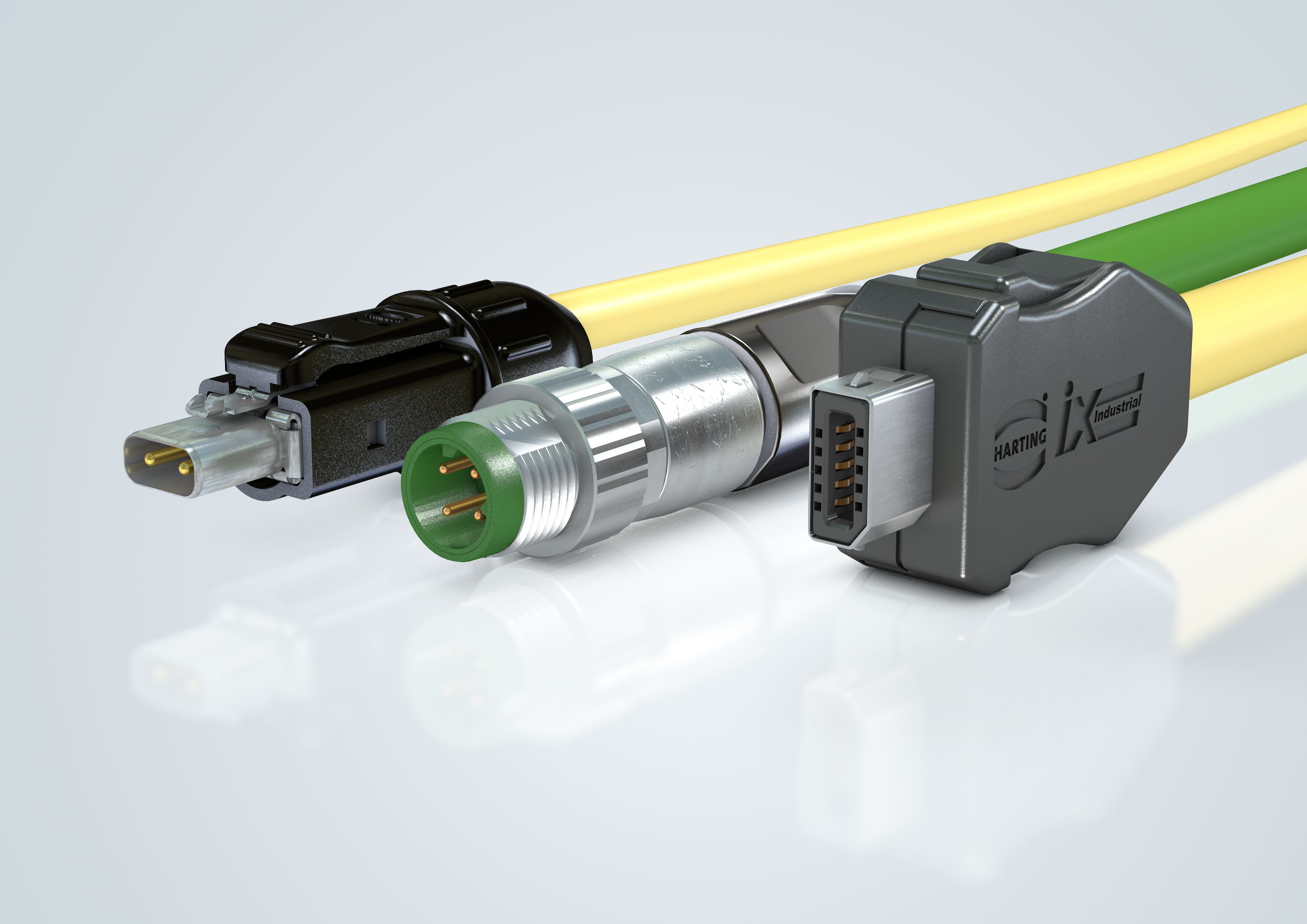

Ethernet Connectors: Ethernet is vital for transferring data in industrial applications. As well as M8 and M12, HARTING have a wide range of robust, miniaturised Ethernet connectors, including the ix Industrial® with a 70% smaller device socket compared to the RJ45 and the T1 Industrial, which delivers Single Pair Ethernet via just one single pair of copper wires.

Jumper Cables and Customised Solutions: To support ETCS, older rolling stock will need upgrading and retrofitting to ensure networks are fast enough to meet future demands and all systems function safely. This can be achieved via jumper cables, which ensure the smooth transmission of power, data and signals throughout the entire train.

HARTING can provide a broad portfolio of both connectors and ready-made cabling solutions. Our design experts can also tailor the layout and design, ensuring all retrofit solutions are suitable for your requirements. We have the capacity to produce project-specific assemblies to suit your needs, including installing components, routing cable harnesses and fabrication. Our design team can also create a 3D CAD visualisation of your build to ensure absolute accuracy before manufacturing begins.