Building manufacturing and supply chain resiliency

Get Out Hardwiring – Today’s World Needs Connectors

The COVID-19 pandemic has had profound effects on every industry. One of the most significantly disrupted industries has been manufacturing and their supply chains. From plant shutdowns and port closures in the earlier days of the pandemic to current global shortages of silicon and lumber and skilled labor shortages, one thing has been undeniable – shortcuts taken in the past are unsustainable in the face of uncertainty.

Due to this upheaval, changes have been happening in industrial markets: companies are making dramatic shifts in manufacturing and supply chain structures to make them more resilient to uncertain conditions and reevaluating staffing in response to skilled labor shortages. Through all of this, one message is clear: the future is coming, and companies must adapt to survive. Connectivity and the right connectivity partner play a critical role in making manufacturing and supply chains more resilient and better prepared for the future.

SHIFT FROM COSTCOMPETITIVENESS TO RISK-COMPETITIVENESS

In 2020, the World Economic Forum in conjunction with leading research group Kearney conducted in interviews with senior operations and supply chain from companies like Siemens, Schneider Electric, and Rockwell to understand how COVID-19 has affected manufacturing and supply chains in order to identify the commonalities between companies that remained stable throughout the pandemic.

They found that companies who were able to maintain their operations effectively without substantial losses already had in place highly flexible, technologically advanced, and risk-averse manufacturing and supply chain models. Those who struggled the most had built their factories and supply chains around being as inexpensive as possible. The World Economic Forum found that the pandemic accelerated a shift that was already happening from highly cost-competitive models to models that are risk-competitive.

They then described the characteristics of a risk-competitive model, which included:

- Flexible and decentralized manufacturing models for increased agility in responding and adapting to changing customer needs

- Investment in advanced manufacturing technologies that enable full transparency and leverage data to make informed decisions

- Fostering strategic relationships and collaboration with partners that offer reliable and local support.

Let’s look at how the right connectivity partner can help companies make the shift to be “risk-competitive.”

CONNECTORIZATION ENABLES FLEXIBLE MANUFACTURING

In the past, a manufacturing floor was static, meaning lines remained relatively the same with upgrades occurring every few years. Machines were placed with the intention that they would perform the same tasks for the duration of their useful life. This, however, has been changing even before the pandemic.

When manufacturing plants were static, connections for bringing power, signal, and data into these old machines could be hardwired. This means all connections going in and out of the machine were permanently fixed to terminal blocks. This was less expensive upfront than adding quick connects on the machines, but there were drawbacks. Installing or disassembling had to be done by a skilled electrician, which was time and cost intensive. Hardwired connections were often miswired, which resulted in downtime and lost revenue.

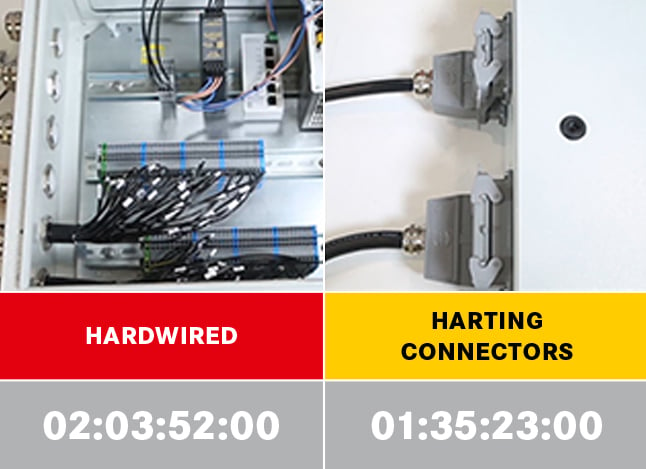

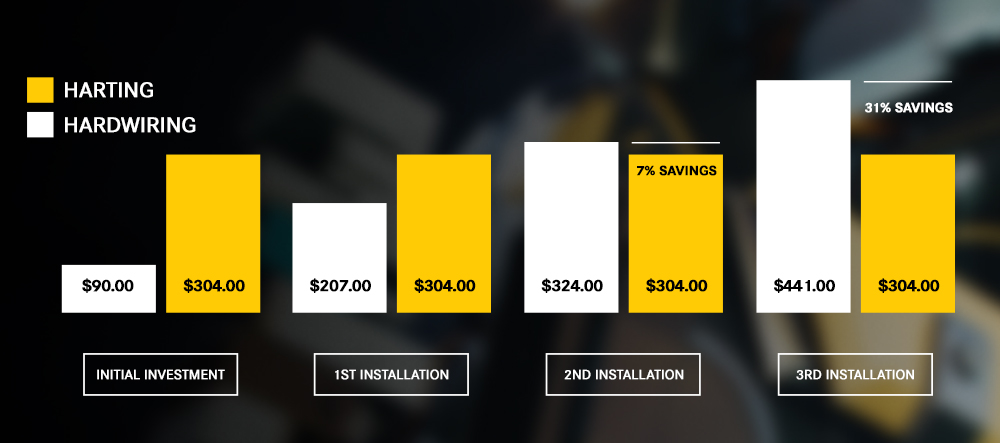

Hardwiring has been an outdated technology for a long time, and many manufacturers and machine builders moved away from the technology years ago. Some machine manufacturers used hardwiring because it was a bit cheaper in the initial machine build than a connector. However, once a machine is disconnected twice, hardwiring is more expensive, and it is the end user who pays for the labor to disconnect and reconnect.

Connectorization, on the other hand, makes flexible manufacturing possible as machines can be disconnected and reconnected quickly, without the need for skilled labor, and with no risk of miswiring. The ability to install without a skilled electrician is critical now due to skilled labor shortages.

Now, connectorization is an absolute must. Manufacturers do not have the time to spend an entire day disconnecting a machine, when a plug and play solution exists. Connectorization, simply put, is the backbone of a successful risk-competitive structure.

ADVANCES IN ETHERNET ENABLE FULL TRANSPARENCY FROM CLOUD TO INDIVIDUAL DEVICES ON A NETWORK

The pandemic proved the importance of transparency in manufacturing and supply chain processes. Transparency enables operations and supply chain to know the status and capabilities of their machines, implement predictive maintenance models to reduce downtime, and utilize data to make informed decisions.

In the past, there were many different data protocols used on industrial communication networks. Ethernet was and is still the leading protocol for computer networks. At the machine, however, serial bus protocols were more common. This created a barrier that made machine data difficult or impossible to access except physically at the machine.

Advances in Ethernet are making Ethernet the standard protocol from the cloud to every sensor on a machine. The most important advancement in this field is the standardization of industrial Single Pair Ethernet. Single Pair Ethernet can send up to 1 Gbit/s Ethernet over just two wires.

As Single Pair Ethernet uses only two copper wires, weight and cost is reduced.

As a result, seamless communication and data gathering from machine to cloud can finally occur allowing data to be processed into actionable insights.

HARTING participates in multiple standards organizations, including IEEE, IEC and TIA, with a focus on standardization of Single Pair Ethernet and is leading a working group within ODVA to define the Single Pair Ethernet standard for industrial environments.

PARTNERS WITH IN-REGION CAPABILITIES MAKE SUPPLY CHAINS RISK RESISTANT

One of the biggest lessons learned from the pandemic is that without the right suppliers, even the most resilient manufacturing and supply chains are at risk.

A supplier who is well-positioned will have the same manufacturing capabilities in multiple regions to prevent supply chain disruptions from local events, offer in-region manufacturing and customization capabilities to support customer specific needs, and have an in-region teams to support their customers on their time zone.

HARTING has been well-positioned for many years in the Americas, allowing us to keep our service levels for customers stable throughout the duration of the pandemic.

HARTING’s structure has always focused on both the global and local levels. HARTING Americas has been an independent group since its founding in 1986 in Illinois, employing a local staff of engineers, product management, finance, and manufacturing to support the unique needs of the Americas. Another aspect of HARTING’s strategy for decades has been to have manufacturing in multiple regions to ensure a reliable supply chain.

Prior to COVID-19, HARTING also made significant investments in North America with a focus on local manufacturing for in-region demand. This became critical for HARTING’s customers during the pandemic, to resounding success. As a result, HARTING Americas has doubled capacity by ramping up shifts in our Illinois plant, focused on both component manufacturing and cable assemblies.

IN CONCLUSION …

The effects of COVID-19 have accelerated existing trends in manufacturing and supply chains. Companies now must make a choice, become risk-competitive or risk losing out on future business.