How connectivity supports future rail transit

Tony Yang, Key Account Manager CRRC, HARTING China

HARTING helps CRRC optimise its train products of rail transit. From catching up to leading, China has kept improving its design and manufacturing levels in rail transit-related equipment in recent years, in which the innovative network connection technology ix Industrial® and its railway converter connector technology Han® HPR HPTC developed by HARTING have also started to play an important role.

The vast and dense rail transit networks in China are like a huge "spider web", with high-speed, safe and intelligent trains running day and night. The design and manufacturing of train-related equipment represent the rapid improvement of the manufacturing levels in China. The innovative network connection technology ix Industrial®and its railway converter connector technology Han® HPR HPTC developed by HARTING are providing a new, simple and reliable connection design for rail transit equipment interface, which is highly advocated and commended by equipment manufacturers.

Solid and reliable network connections

All types of on-board equipment should be able to deliver strong and reliable performance in order to ensure safe, fast and intelligent operation. Recently, CRRC, a major equipment manufacturer in China's rail transit industry, adopted ix Industrial®, an innovative network interface technology from HARTING, in the electrical design and R&D of relevant equipment. As a more reliable and miniaturised alternative compared to the traditional RJ45 network interface, ix Industrial® fully complies with IEC 61076-3-124, the international standard for connectors of electronic equipment.

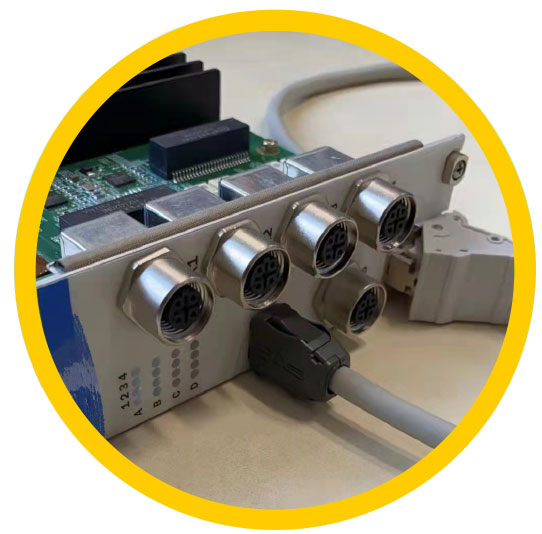

Generally speaking, in the electrical control cabinet of each carriage, standard industrial 3U chassis is usually used, in which a certain number of communication boards are fitted. However, due to the limited space, especially on the 160 mm * 100 mm board, the R&D experts are striving to reducing the size of the network interface as much as possible so as to integrate more and more electronic components.

As CRRC's R&D staff explained, "in order to meet the requirements of extended functions, based on the previous design, three M12 interfaces and one to two RJ45 interfaces are required on a standard board, which will occupy a large space on a board with very limited space."

In the PCB board design of train network equipment, CRRC needs to complete the normal debugging of equipment and functions such as downloading programs through network interfaces. The innovative technology ix Industrial® realises active locking through two stable metal snap hooks instead of the traditional Ethernet interface used by RJ45. The crimped connections are applied between cable sheath and plug, which meet the demands for high impact and vibration resistance stipulated by the EN 50155 railway specification, and while ensuring the long service life of 5,000 mating cycles. In operation, this interface firmly fixes the socket to the PCB board through five solid THR shielding contacts, which can prevent damage caused by excessive force.

"This should help us solve the problems of easy fracture and occasional disconnection of RJ45 locking tab previously encountered." The responsible CRRC R&D staff are convinced that HARTING's connectors can provide high reliability for the design of rail transit equipment thanks to its high quality and leading interface technology, and represents an advanced connection technology worthy of continuous verification and practical application.

Compact size and simple connection

Compared with the typical RJ45 socket, ix Industrial® interface has reduced the space occupied by 75 %. On top of that it greatly improves the simplicity of plugging in by comparison with the M12 interface, due to the fact that the ix Industrial® adopts the quick plug connection instead of the traditional manual screw connection, making the operation much simpler and more efficient in such a narrow space.

Reliable supply under harsh conditions

In the design of the jumper interface of traction vehicles, CRRC has considered adopting a simpler standard split-type shell, which can be installed from the inside and outside of the vehicle. This is not only durable, but also easy to maintain. HARTING Han® HPR HPTC is a transformer interface specially developed for customers in the railway industry and optimised for outdoor scenarios. With this design, the converter can be connected to the transformer through the plug-pull mode.