Products & Solutions

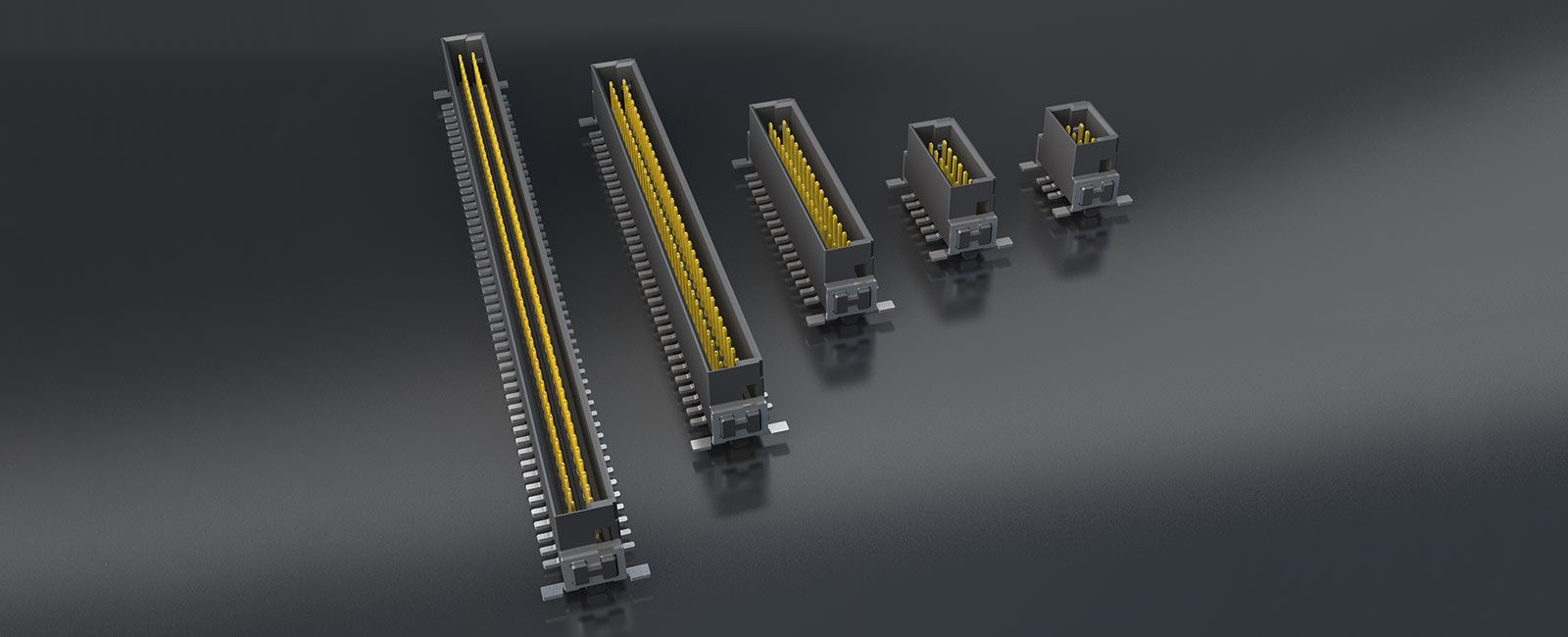

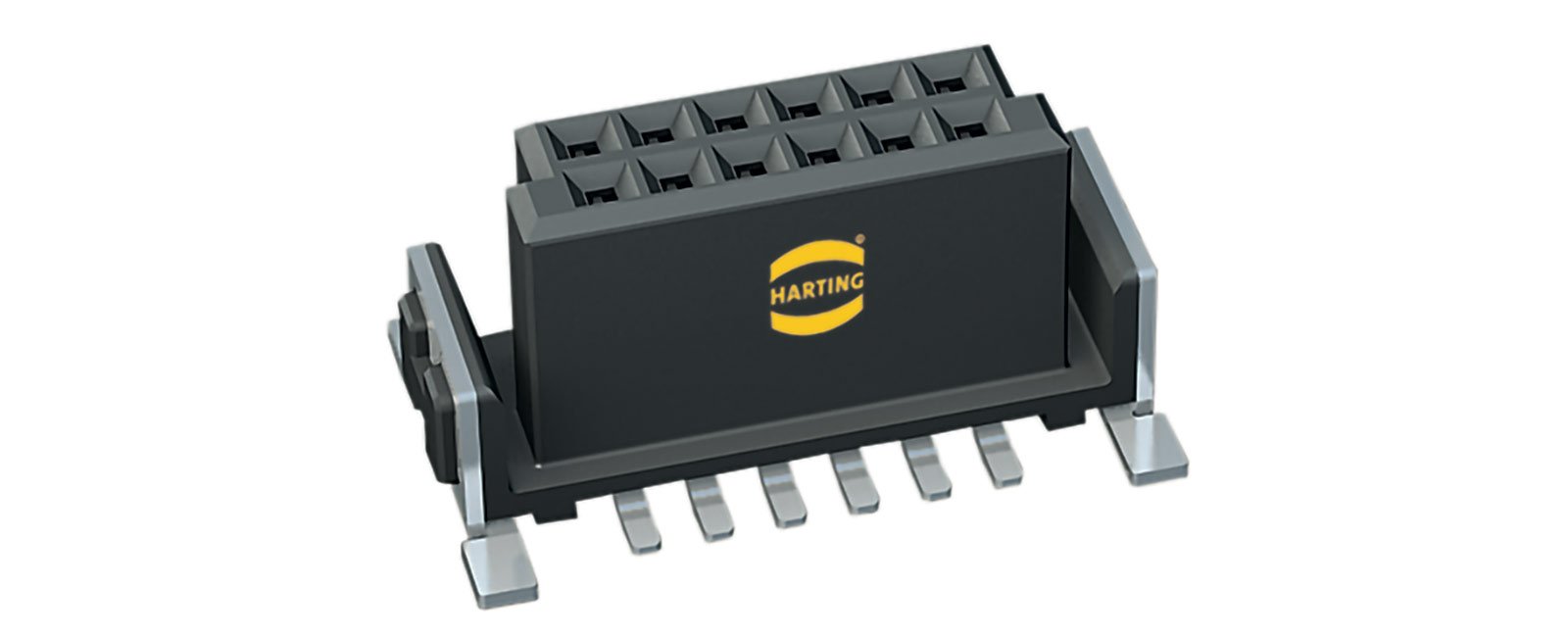

HARTING har-flex® PCB Connectors

Why har-flex®?

Smaller, more powerful and at the same time more robust is the credo in all areas on the way to I4.0. Due to the miniaturized design and the high variability of the PCB har-flex® connectors, device manufacturers have a freely scalable connection technology that meets the requirements of miniaturization.

What are PCB Connectors?

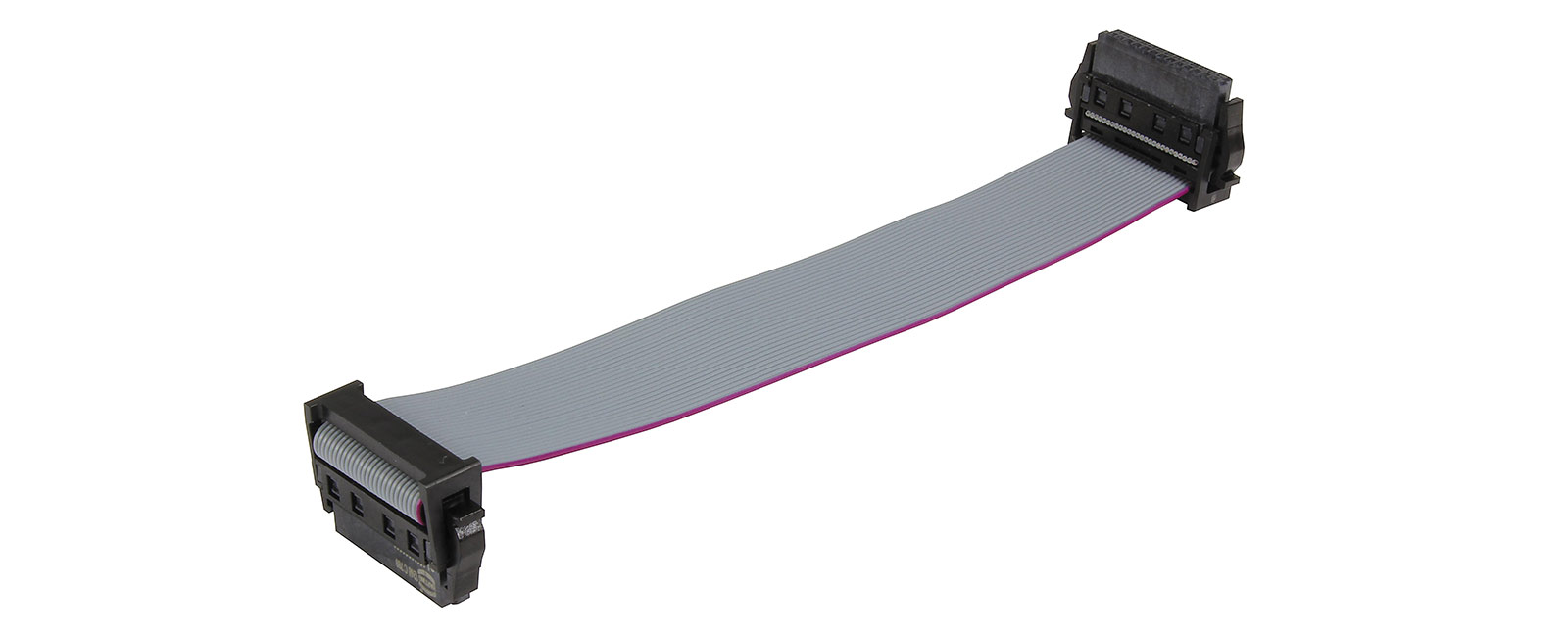

PCB connectors are connectors that are soldered to a printed circuit board, providing a contact point for a cable or wire attachment. PCB connectors enable other devices or boards to directly interface with the circuit board. Subcategories of PCB connectors include: board to board connectors, IDC connectors, card connectors, ribbon cable connectors, flat cable connectors.

PCB connectors for all-purpose use

- Robust and miniaturized design

- Efficient connections to the PCB thanks to fully automated processing

- Many pin counts available

- Product diversity with different connector styles

With the har-flex® connectors, HARTING has designed a series of PCB connectors for all-purpose use in and on the device.

Continuous Scalability

A special feature of the har-flex® mezzanine connectors is their continuous scalability, with all pin counts available from 6 to 100. This makes custom solutions possible for all customer requirements.

Control cabinet space is money in machine and plant construction. Depending on the requirements of the customer application and the packing density of the I / O's, stringing together 50 or more I / O modules is quite common. It soon becomes clear that each millimeter saved in the width of the individual module has a significant influence on the space saved in the control cabinet.

What are Mezzanine Connectors?

Mezzanine connectors provide an electrical connection between two parallel PCBs in a stacking configuration. A stacking configuration is used in applications where a slim and/or small design is needed. An example of this would be a camera or LCD display.

1. Various pin counts available

2. Customized IDC cable assemblies

3. Additional SMT hold-downs

4. Locking levers and strain relief

5. Automatic assembly possible

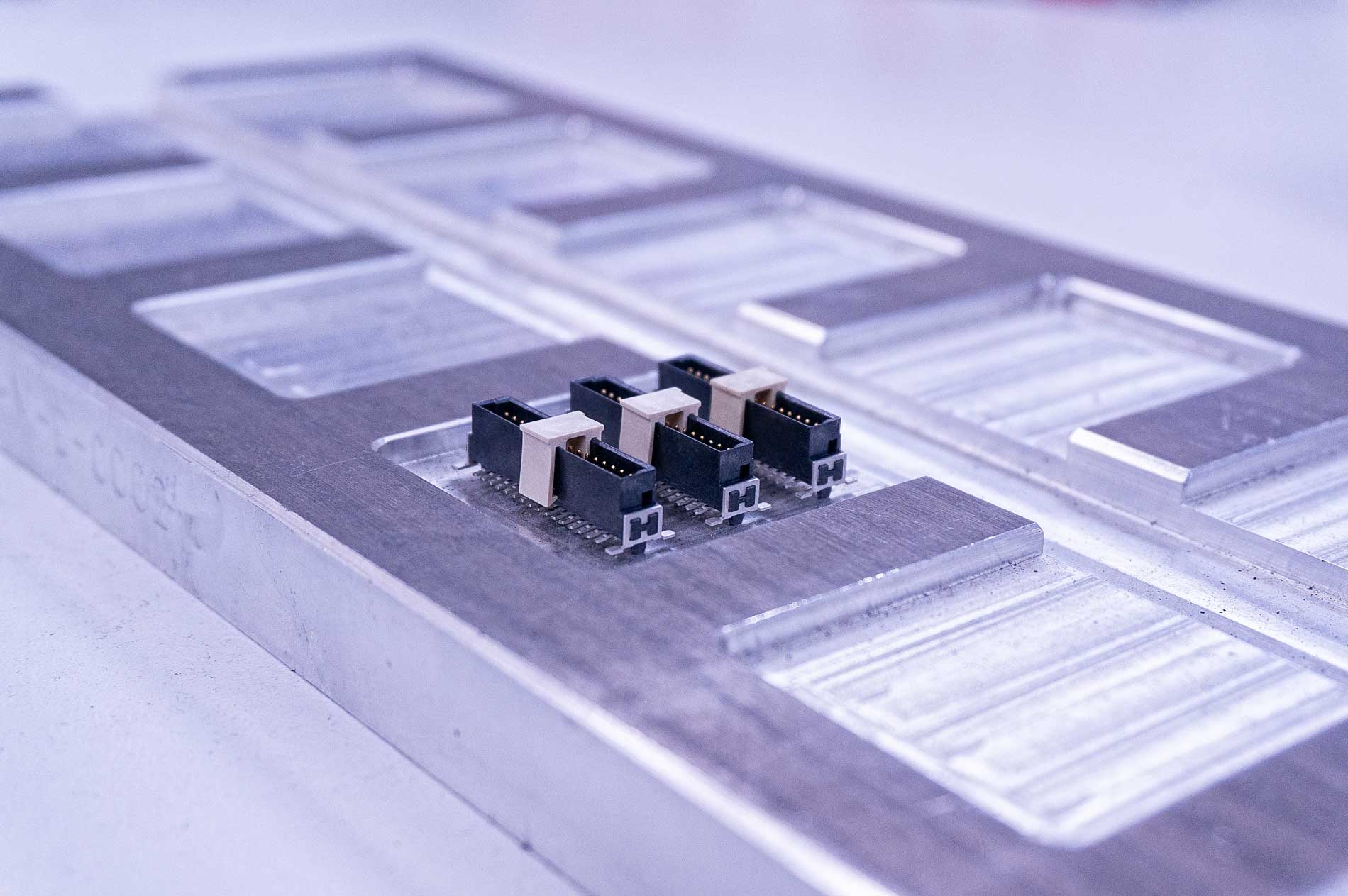

6. NEW variants with the THR termination technique

The new har-flex® THR variants are intended for applications with demanding mechanical conditions. THR stands for Through Hole Reflow: this termination technique uses side-mounted hold-downs. The connectors combine the mechanically stable solder joints of through-hole technology with the automatic assembly benefits of SMD components. The signal contacts are also designed with the SMT termination technique, so that separating the conducting paths within the circuit board remains as simple as possible.