Circular Connectors

As one of the largest manufacturers of industrial connection technology, HARTING has a comprehensive portfolio of circular connectors in all common sizes and codings. The product range includes circular connectors, overmoulded cable assemblies as well as PCB connectors and panel feed throughs that can be assembled on-site.

Learn from our experts

Get updated and learn: watch all recordings of our annual digital conference HARTING Industrial Ethernet Week from February 2024.

Which circular connector is the right one?

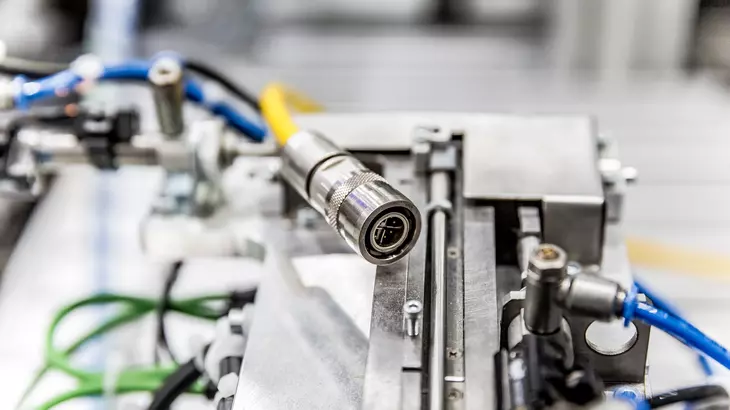

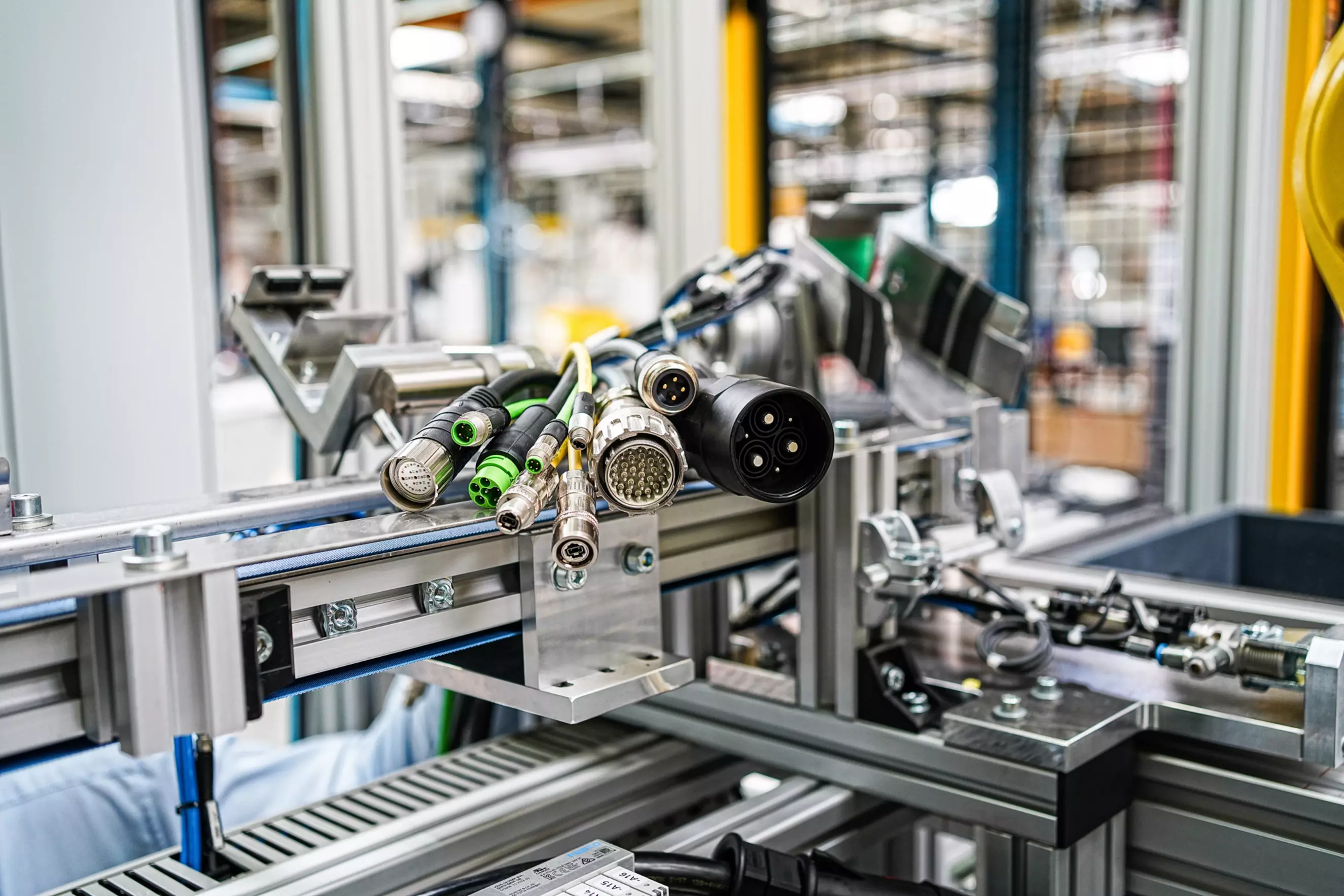

Circular connectors are among the pluggable interfaces most commonly found in industrial applications. Electrical connections through circular connectors are safely protected from external influences. Touch, dust, dirt, grease and oils as well as moisture are safely kept away. Even with vibrations and movements, which are common in industry and traffic engineering, the stable connection achieved with round connectors is impressive. The range of applications is wide: sensors, drives and converters, network components and operating devices are typical areas of application for circular connectors.

Standardised sizes and mating faces provide safety

The size and mating faces of circular connectors generally correspond to standardised thread sizes. This ensures that circular connectors from different manufacturers are compatible with each other.

Each size has typical areas of application. In addition to the desired or available attachment size, these also result from the physical performance data such as the number and cross-section of the wires and the current carrying capacity. HARTING has circular connectors with metric thread (M) as well as thread sizes in inches. Metric circular connectors are one of the most common interfaces worldwide. Their origin is in the shape of their locking mechanism. This is based on the dimensions and standardisation of screws, which comply with ISO 1502. As such, metric circular connectors always have the fixed defined diameter in millimeters in the locking area, as do all standardised screw connections. M8 = 8 millimeter etc.

Coding prevents mismating

The mating faces of circular connectors are coded to prevent mismating. The coding is incorporated into the inner shape of the insulation bodies. M8 and M12 circular connectors have codings that visually resemble letters used to distinguish the coding and the corresponding application.

Connecting circular connectors onsite

A secure and permanently stable connection of the wires to the male contact/sleeve in the connector is a basic requirement for error-free transmission of data, signals and power. Various connection types are available, which have their benefits depending on the type and use of the connector. Connectors that can be assembled on-site can be crimped without tools or with special crimping pliers.

The housing protects against ambient conditions

The connector housing forms the external protection against the ambient conditions. Plastic or metal housings are used. In addition to the robust design, metal housings also provide shielding against electromagnetic interference (EMC). The transition from the housing to the cable is made via cable gland, crimp flange or overmoulding.

Knowledge

Engineering Data & Services

CAD data, product data manager, distributors availability, free samples & more.

Discover the HARTING Engineering Data & Services to support your project as best as possible. For each product in our digital catalogue you will find further engineering data and services:

CAD data, data sheets and type sheets

Product selectors with multiple attributes

Individually data packages

Configuration and customization

Individual notes and deratings

Free sample service